- Alguna consulta ?

- +56 9 42891707

- +56 9 40281901

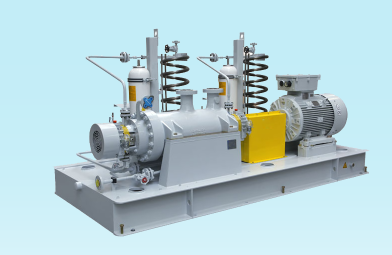

Bomba Centrifuga Horizontal Multietapa BMRS Series

28 agosto, 2019

Bomba de proceso petroquimico tipo OHF/C Series

28 agosto, 2019Product type-description:

BMRD petrol-chemical process pump is a multi-stage centrifugal pump of horizontal, double shell, segment type, which impellers are arranged in the same direction or back-to-back, radially split, horizontal center line support type.It’s designed according to API610,BB5 type.

This kind of pump is radial diffuser structure,concentrically-braced frame,inlet and outlet are arranged at pump inlet.First stage impeller and secondary impeller have different design concept, the former considers pump’s cavitation performance, and the latter considers pump’s efficiency,which make the whole pump have excellent cavitation performance and efficiency.

This series of pumps is designed strictly in accordance with the standard in terms of pump support, bearing arrangement, reservation interface, cooling and washing, cavity structure etc.

This series of pumps has good hydraulic power,comprehensive spectrum,high efficiency and anti-cavitation.According to a large number of experimental data combined with hydraulic analysis software,its hydraulic performance reaches current international advanced level.

Parameters:

Standard:API610

Capacity:20~1000m3/h

Head: ~3000m

Pressure:35MPa

Temperature:-80~450ºC

Application:It’s mainly used to convey all kinds of clean or flammable, explosive, toxic media such as oil, refined oil, liquefied petroleum gas, light hydrocarbon, boiler feed water.

Cross-section Diagram:

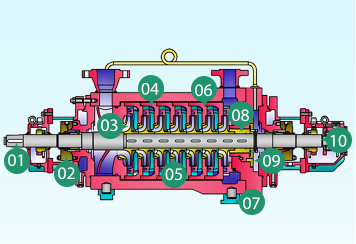

1.BMRD Basic Type Structure Chart

1.Conical shaft extension design: when shaft diameter is greater than 60mm, the product uses conical shaft extension design, which is advantageous to installation and disassembly of the coupling, the bearing and the seal .

2.Standard seal configuration:chamber size is completely according to the API682 standard, and it can be configured with multiform seal flushing and cooling plans or configured according to user requirements.

3.Good cavitation performance: suction type impeller, good cavitation performance.

4.Convenient inspection and maintenance: the inner core adopts total extraction structure and can realize the maintenance and inspection of the pump without moving the inlet and outlet pipes.

5. Friction vice configuration: pump body and impeller are provided with seal rings,and its gap and hardness difference are in line with API610 standard. Spare parts replacement is convenient and service life is long.

6.High temperature resistance: at normal temperature, middle seal surface uses «O-type ring»;at high temperature, the use of «metal surface VS metal surface» design.

7.Many kinds of bearing options: self – lubrication or forced lubrication of bearing structure can be chosen according to shaft power and speed.

8.Guide set: the cylinder body is provided with guide key and locating pin. When high temperature medium is transported, the pump extends to non-driving end, and the connection with driving machine is not affected.

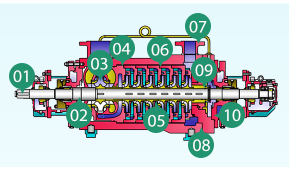

2.BMRD First-stage Double-suction Structure Chart

1.Conical shaft extension design: when shaft diameter is greater than 60mm, the product uses conical shaft extension design, which is advantageous to installation and disassembly of the coupling, the bearing and the seal .

2.Standard seal configuration:chamber size is completely according to the API682 standard, and it can be configured with multiform seal flushing and cooling plans or configured according to user requirements.

3.Good cavitation performance: suction type impeller, good cavitation performance.

4.Convenient inspection and maintenance: the inner core adopts total extraction structure and can realize the maintenance and inspection of the pump without moving the inlet and outlet pipes.

5.Friction vice configuration: pump body and impeller are provided with seal rings,and its gap and hardness difference are in line with API610 standard. Spare parts replacement is convenient and service life is long.

6.High temperature resistance: at normal temperature, middle seal surface uses «O-type ring»;at high temperature, the use of «metal surface VS metal surface» design.

7.Inlet and outlet arrangement form:the normal way is “over-entering and over-out” structure,but also takes other ways according to user requirements .

8.Guide set: the cylinder body is provided with guide key and locating pin. When high temperature medium is transported, the pump extends to non-driving end, and the connection with driving machine is not affected.

9.Balanced structure:Drum-plate-drum balance mechanism effectively avoids «flash» phenomenon, at the same time, greatly improves service life of the bearing and running stability.

10.Reliability assurance:pump body, pump cover and other important parts are manufactured by means of forging process, and 3mm corrosion allowance is guaranteed to ensure pump safety and stability under design pressure.

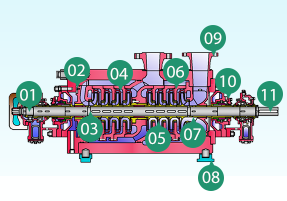

3.BMRDZ Self-balancing Structure Chart

1.Reliability assurance:pump body, pump cover and other important parts are manufactured by means of forging process, and 3mm corrosion allowance is guaranteed to ensure pump safety and stability under design pressure.

2.Impeller locating form: the impeller adopts sliding structure and tandem locating, which protects the shaft and increase its strength.Convenient assembly and disassembly.

3.Convenient inspection and maintenance: the inner core adopts total extraction structure and can realize the maintenance and inspection of the pump without moving the inlet and outlet pipes.

4.Impeller arrangement form:rotor impeller of symmetrical arrangement, automatically balanced axial force and non-special balance mechanism improve product reliability.

5.High temperature resistance: at normal temperature, middle seal surface uses «O-type ring»;at high temperature, the use of «metal surface VS metal surface» design.

6.Good cavitation performance: suction type impeller, good cavitation performance. In order to obtain better cavitation performance, first-stage impeller can select double-suction structure.

7.Guide set: the cylinder body is provided with guide key and locating pin. When high temperature medium is transported, the pump extends to non-driving end, and the connection with driving machine is not affected.

8.Inlet and outlet arrangement form:the normal way is “over-entering and over-out” structure,but also takes other ways according to user requirements .

9.Standard seal configuration:chamber size is completely according to the API682 standard, and it can be configured with multiform seal flushing and cooling plans or configured according to user requirements.

10.Conical shaft extension design: when shaft diameter is greater than 60mm, the product uses conical shaft extension design, which is advantageous to installation and disassembly of the coupling, the bearing and the seal .